Our Products

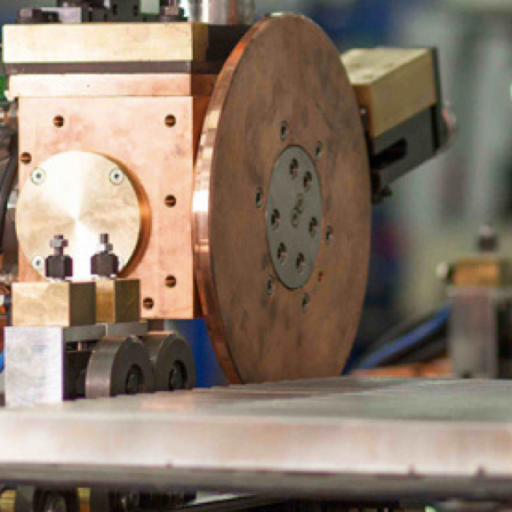

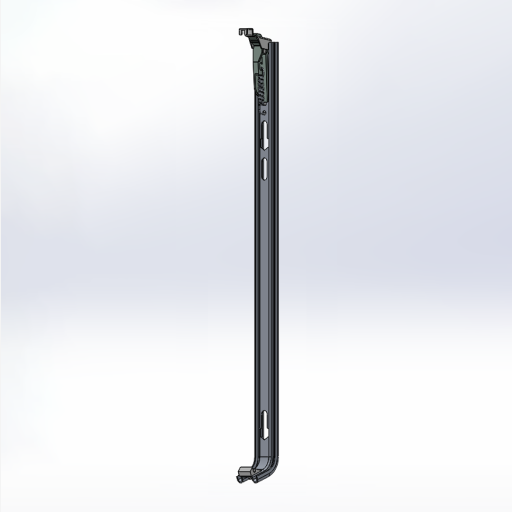

Welding Disc for Panel Radiators Welding Line

Material description: Usage of aprox. 1% of Cobalt, 1$ of Nickel and 0,5% of Berlium contains solutioning and aging heat treatment of hot forging with post-high hardness and strength obtained, of the copper alloys good thermal conductivity. The heat treatment conditions can be obtained by different combinations of displacement with the hardness and conductivity.

Category:Copper Alloys Products

Product Code:

PRODUCT FEATURES

TECHNICAL INFORMATION

Sphere of usage: Resistance welding electrodes, electrode holders and seam welding discs. Plunger Alümyum pressure casting, plastic injection molding machines, parts, and cooling spray nozzles are used as free standing insert. In non-ferrous metals, casting mold, mold cooling is used as a free standing insert. Good surface quality, uniform and rapid icrease in the rate of work due to the cooling properties, is highly resistant , so You will not be disappointed while using it in your business.

Product Groups

Quality and Certificates

© 2024 All Rights Reserved